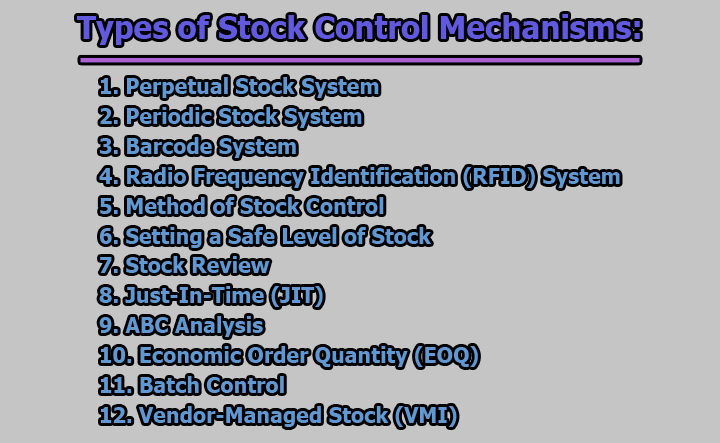

Types of Stock Control Mechanisms:

In the dynamic landscape of modern business, effective stock control mechanisms play a pivotal role in the success and sustainability of organizations across various industries. The term “stock control” encompasses a comprehensive set of strategies and systems designed to manage and optimize the flow of inventory within a company. These mechanisms are essential for maintaining an equilibrium between meeting customer demands, minimizing holding costs, and ensuring operational efficiency. Let’s explore in detail the various types of stock control mechanisms:

1. Perpetual Stock System:

The perpetual stock system is a continuous inventory management approach that provides real-time visibility into the levels of products in stock. Here are key aspects of the perpetual stock system:

1.1 Real-time Tracking: Every inventory transaction, such as sales, purchases, returns, and adjustments, is immediately recorded in the system. This ensures that the recorded stock levels are always up-to-date and accurate.

1.2 Automation: The perpetual system often involves automation through the use of computerized systems and software. Barcode scanners, RFID technology, and point-of-sale (POS) systems are commonly employed to automate the data entry process, minimizing errors associated with manual tracking.

1.3 Accuracy and Precision: With continuous updates and real-time tracking, the perpetual system provides a high level of accuracy. This accuracy is crucial for businesses that require precise control over their inventory levels, especially in fast-paced environments where stock turnover is high.

1.4 Inventory Valuation: The perpetual system facilitates accurate valuation of inventory at any given moment. This is essential for financial reporting and helps businesses understand the current value of their assets.

1.5 Supply Chain Integration: Many businesses integrate the perpetual stock system with their supply chain management processes. This integration allows for seamless coordination between suppliers, manufacturers, distributors, and retailers, ensuring a more efficient and responsive supply chain.

2. Periodic Stock System:

The periodic stock system is an inventory management method where physical counts of inventory are conducted at specific intervals. Here are the key aspects of this system:

2.1 Intermittent Updates: Unlike the perpetual system, the periodic system does not provide continuous updates on inventory levels. Instead, updates occur periodically, often at the end of a week, month, quarter, or fiscal year.

2.2 Cost-Efficiency: The periodic system is often more cost-effective in terms of setup and maintenance. It may be suitable for businesses with lower transaction volumes or those where real-time tracking is not critical.

2.3 Discrepancies and Adjustments: Since there is a time gap between updates, discrepancies between recorded and actual stock levels may occur. Regular physical counts are conducted to identify these discrepancies, and adjustments are made to the inventory records.

2.4 Resource Requirements: Physical counting requires manpower and time. Businesses need to allocate resources for accurate and thorough counting processes to minimize errors and ensure that discrepancies are identified and addressed.

3. Barcode System:

The barcode system is a technology-driven stock control mechanism that involves assigning unique barcodes to each product. These barcodes are scanned during various inventory transactions. Here are the key points related to the barcode system:

3.1 Unique Identification: Each product is assigned a unique barcode, which serves as a distinct identifier. This allows for accurate and efficient tracking of individual items within the inventory.

3.2 Quick and Accurate Data Entry: Barcodes are scanned using handheld devices, streamlining the data entry process. This reduces the likelihood of manual errors associated with traditional data entry methods, such as manual keying of product codes.

3.3 Integration with Software: Barcoding systems are often integrated with inventory management software. This integration enables seamless communication between the barcode scanners and the central inventory database, ensuring real-time updates.

3.4 Increased Efficiency: The use of barcodes significantly speeds up various inventory-related processes, including receiving shipments, recording sales, and conducting stock counts. This efficiency is particularly valuable in retail environments with high transaction volumes.

3.5 Enhanced Accuracy in Order Fulfillment: Barcodes play a crucial role in order fulfillment accuracy. Scanning barcodes during the picking and packing processes helps ensure that the right products are selected and shipped to customers.

3.6 Inventory Visibility: Barcode systems provide real-time visibility into inventory levels, aiding businesses in making informed decisions about stock replenishment, reordering points, and overall inventory management.

4. Radio Frequency Identification (RFID) System:

The Radio Frequency Identification (RFID) system is a more advanced technology compared to barcoding. It uses radio frequency signals to identify and track items equipped with RFID tags. Here are the key aspects of the RFID system:

4.1 Tagging and Tracking: Products are equipped with RFID tags containing electronically stored information. RFID readers emit radio frequency signals that interact with these tags, allowing for the wireless and contactless identification and tracking of items.

4.2 Real-Time Visibility: RFID provides real-time visibility into inventory levels without requiring a direct line of sight between the reader and the tags. This makes RFID particularly useful in environments where quick and accurate tracking of items is crucial.

4.3 Automation and Efficiency: RFID systems streamline inventory processes by automating data collection. Multiple RFID tags can be read simultaneously, speeding up processes such as receiving shipments and conducting inventory counts. This automation reduces the need for manual intervention.

4.4 Accuracy and Error Reduction: RFID technology minimizes errors associated with manual data entry and human intervention. The automated nature of RFID systems ensures a higher level of accuracy in tracking inventory movements.

4.5 Applications Beyond Inventory: RFID technology goes beyond inventory management. It is used in supply chain visibility, asset tracking, and even in enhancing the customer experience, such as in retail environments for quick and seamless checkouts.

4.6 Initial Implementation Costs: While RFID offers numerous benefits, the initial implementation costs can be higher than traditional barcoding systems. However, the long-term advantages in terms of efficiency and accuracy often justify the investment.

5. Method of Stock Control:

Stock control methods refer to the approaches businesses use to manage their inventory. Three common methods include:

5.1 First-In-First-Out (FIFO): This method assumes that the first items placed in inventory are the first to be sold or used. It is particularly relevant for perishable goods and ensures that older inventory is used before newer stock.

5.2 Last-In-First-Out (LIFO): LIFO assumes that the most recently acquired items are the first to be sold or used. While less common due to its impact on financial reporting, LIFO can be beneficial during periods of inflation.

5.3 Weighted Average: This method calculates the average cost of all units in inventory. It is suitable for businesses where products are commingled, and it provides a more stable cost per unit during price fluctuations.

5.4 Impact on Financial Statements: The choice of stock control method affects the valuation of inventory and, consequently, the cost of goods sold (COGS) reported in financial statements. Different methods may lead to variations in reported profitability.

5.5 Compliance and Reporting: Businesses need to adhere to specific accounting standards and regulations when selecting a stock control method. The chosen method should align with generally accepted accounting principles (GAAP) or International Financial Reporting Standards (IFRS).

6. Setting a Safe Level of Stock:

Setting a safe level of stock involves determining the minimum quantity of a product that a business should have on hand to avoid stockouts during normal lead times. Key aspects of this mechanism include:

6.1 Lead Time Consideration: The safe level is influenced by the time it takes to replenish stock. Businesses need to account for the lead time between placing an order and receiving the goods to ensure that they have sufficient stock during this period.

6.2 Demand Variability: Safe levels are influenced by variations in demand. Businesses that experience fluctuating demand need to set higher safe levels to accommodate peak periods and avoid stockouts.

6.3 Buffer Stock: The safe level often includes a buffer stock, which acts as a safety net to account for unforeseen circumstances such as sudden increases in demand, supplier delays, or unexpected disruptions in the supply chain.

6.4 Strategic Planning: Setting an appropriate safe level requires strategic planning and analysis of historical data, market trends, and other factors influencing demand and supply. It is a proactive approach to ensure continuity in operations.

6.5 Minimizing Stockouts: The primary goal of setting a safe level is to minimize the risk of stockouts, which can lead to lost sales, dissatisfied customers, and potential damage to the reputation of the business.

6.6 Reorder Point: The safe level is often tied to the reorder point, which is the inventory level at which a new order should be placed to replenish stock before it falls below the safe level.

7. Stock Review:

Stock review involves regularly analyzing and evaluating the levels of inventory to make informed decisions about stock replenishment, adjustments to reorder points, and overall inventory management. Here are key aspects of stock review:

7.1 Frequency of Reviews: Businesses conduct stock reviews on a regular basis, with the frequency determined by factors such as the nature of the products, demand variability, and overall supply chain dynamics. Some businesses may perform reviews weekly, while others may do so monthly or quarterly.

7.2 Data Analysis: During stock reviews, businesses analyze historical sales data, current demand trends, and other relevant factors. This data-driven approach helps in understanding patterns, identifying seasonality, and making accurate forecasts.

7.3 Reorder Point Adjustments: Based on the analysis, businesses may adjust the reorder points for different products. Reorder points indicate the inventory level at which a new order should be placed to replenish stock. Adjusting these points ensures that orders are placed in a timely manner.

7.4 Identifying Slow-Moving Items: Stock reviews help in identifying slow-moving or obsolete items in the inventory. Businesses can take proactive measures to address these items, such as implementing promotions, discounts, or discontinuing products that no longer align with market demand.

7.5 Optimizing Stock Levels: The ultimate goal of stock reviews is to optimize stock levels, ensuring that inventory is aligned with actual demand. This prevents overstocking and stockouts, leading to better working capital management and improved customer satisfaction.

7.6 Integration with Technology: Modern businesses often use inventory management software and analytics tools to streamline the stock review process. These tools provide real-time data, advanced reporting, and forecasting capabilities to enhance decision-making.

8. Just-In-Time (JIT):

Just-In-Time (JIT) is a stock control strategy where inventory is ordered and received just in time for production or sale. Key aspects of JIT include:

8.1 Reduced Holding Costs: JIT minimizes the need for large inventories, thereby reducing holding costs associated with storage, insurance, and security. This allows businesses to operate with lower working capital and more efficient use of resources.

8.2 Efficient Supply Chain Management: JIT relies on efficient supply chain management to ensure that raw materials and components are delivered precisely when needed. This requires close collaboration with suppliers to establish reliable and timely delivery schedules.

8.3 Minimized Wastage: By receiving materials just in time for production, businesses can minimize the risk of wastage due to spoilage, obsolescence, or changes in market demand. This is particularly advantageous for industries with perishable or rapidly changing products.

8.4 Flexibility and Responsiveness: JIT enhances the flexibility and responsiveness of a business to changes in customer demand. With a lean inventory system, businesses can quickly adapt to fluctuations in the market and avoid excess inventory during periods of reduced demand.

8.5 Quality Control: JIT places a strong emphasis on maintaining high product quality. With a reduced inventory buffer, any defects or issues in the production process are immediately apparent, allowing for quick corrective actions.

8.6 Continuous Improvement: JIT is closely associated with the philosophy of continuous improvement. It encourages businesses to identify and eliminate inefficiencies in the production and supply chain processes, leading to ongoing improvements in operational efficiency.

9. ABC Analysis:

ABC analysis is a technique used to categorize inventory into three groups (A, B, and C) based on their value and importance. Here are the key aspects of ABC analysis:

9.1 High-Value Items (A): Category A items are high-value, typically representing a small percentage of the total number of items in inventory but contributing significantly to the overall inventory value. These items often require tight control and more frequent monitoring.

9.2 Moderate-Value Items (B): Category B items have a moderate value and importance. They fall between the high-value A items and the low-value C items. Management of B items involves a balanced approach, with less frequent monitoring compared to A items.

9.3 Low-Value Items (C): Category C items are low-value items that, individually, contribute less to the total inventory value. These items are often more numerous but require less stringent control and monitoring.

9.4 Resource Allocation: ABC analysis helps businesses allocate resources more effectively. With a focus on high-value items (A), businesses can prioritize efforts to optimize the management of these critical products.

9.5 Inventory Stratification: ABC analysis stratifies inventory into different categories, allowing businesses to apply different management strategies based on the importance of each category. This segmentation aids in setting appropriate stock control policies for each group.

9.6 Risk Management: By identifying and prioritizing high-value items, businesses can manage the risk associated with potential stockouts or overstocking. This strategic approach ensures that critical items are given the necessary attention and resources.

10. Economic Order Quantity (EOQ):

Economic Order Quantity (EOQ) is a formula used to calculate the optimal order quantity that minimizes the total inventory costs, including holding costs and ordering costs. Here are the key aspects of EOQ:

10.1 Ordering Costs: EOQ takes into account the costs associated with placing orders, such as paperwork, communication, and processing expenses. The goal is to find the order quantity that minimizes these costs while balancing against holding costs.

10.2 Holding Costs: Holding costs include expenses related to storing inventory, such as rent, utilities, insurance, and the opportunity cost of tying up capital in inventory. EOQ seeks to find the order quantity that minimizes the holding costs associated with excess inventory.

10.3 Formula: The EOQ formula considers the demand for the product, the ordering cost per order, and the holding cost per unit. The formula is designed to find the order quantity that optimally balances the costs associated with ordering and holding inventory.

10.4 Reorder Point: EOQ is closely related to the concept of reorder points. Once the EOQ is calculated, businesses can determine when to reorder products to maintain optimal inventory levels and minimize costs.

10.5 Batch Ordering: EOQ promotes the concept of batch ordering, where larger quantities are ordered less frequently. This reduces the frequency of orders, minimizing ordering costs, while still ensuring that holding costs are kept at an optimal level.

10.6 Assumptions and Limitations: EOQ relies on certain assumptions, such as constant demand and known and constant ordering and holding costs. It may not be suitable for all scenarios, especially those with variable demand or fluctuating costs.

11. Batch Control:

Batch control is a stock control mechanism that involves managing inventory in specific batches or lots. This is particularly important in industries where products have shelf lives, expiration dates, or where traceability of batches is crucial. Key aspects of batch control include:

11.1 Lot Identification: Products are grouped into lots or batches, and each batch is assigned a unique identifier. This identifier allows for traceability throughout the supply chain and facilitates targeted recalls if necessary.

11.2 Shelf Life Management: Batch control is essential for managing products with limited shelf lives. Businesses need to monitor and control the rotation of batches to ensure that older batches are used or sold before newer ones.

11.3 Quality Control: In industries where product quality can vary between batches, batch control helps in implementing quality control measures. Businesses can track and trace any quality issues back to specific batches, enabling targeted corrective actions.

11.4 Regulatory Compliance: Batch control is often a regulatory requirement in industries such as pharmaceuticals, food, and chemicals. Compliance with regulations ensures that businesses meet quality standards and can provide accurate information about the origin and history of products.

11.5 Efficient Recall Procedures: In the event of a product recall, batch control allows businesses to pinpoint the affected batches quickly. This facilitates a more efficient and targeted recall process, reducing the impact on both consumers and the business.

11.6 Inventory Visibility: Batch control enhances inventory visibility by providing detailed information about the characteristics and history of each batch. This visibility is crucial for managing stock levels, reducing waste, and ensuring product quality.

12. Vendor-Managed Stock (VMI):

Vendor-Managed Stock (VMI) is a collaborative supply chain arrangement where the supplier or vendor takes responsibility for managing the inventory levels of their products at the customer’s location. Key aspects of VMI include:

12.1 Collaborative Planning: VMI requires close collaboration between the supplier and the customer. The supplier monitors the customer’s inventory levels, demand patterns, and other relevant data to make informed decisions about replenishment.

12.2 Automatic Replenishment: In a VMI system, the supplier is authorized to automatically replenish the customer’s inventory based on predefined criteria such as stock levels, reorder points, and consumption patterns. This minimizes the need for manual order placement by the customer.

12.3 Reduced Bullwhip Effect: VMI helps in reducing the bullwhip effect, which is the amplification of demand variability as it moves up the supply chain. With real-time information sharing, the supplier can respond more accurately to actual customer demand, avoiding unnecessary fluctuations.

12.4 Efficient Supply Chain: VMI contributes to a more efficient and responsive supply chain. By allowing the supplier to take a more active role in inventory management, businesses can achieve better coordination, reduce lead times, and improve overall supply chain performance.

12.5 Risk Sharing: VMI can involve a sharing of risks and rewards between the supplier and the customer. The supplier may take on more responsibility for managing inventory, but this can result in benefits such as reduced stockouts, lower holding costs, and improved customer satisfaction.

12.6 Data Sharing and Technology: Successful implementation of VMI often requires advanced information systems for real-time data sharing between the supplier and the customer. This technology facilitates accurate monitoring, timely replenishment, and effective collaboration.

In conclusion, implementing the appropriate stock control mechanisms depends on the nature of the business, the industry, and the specific characteristics of the products involved. A combination of these mechanisms may be used to create a comprehensive and effective stock control strategy.

Assistant Teacher at Zinzira Pir Mohammad Pilot School and College