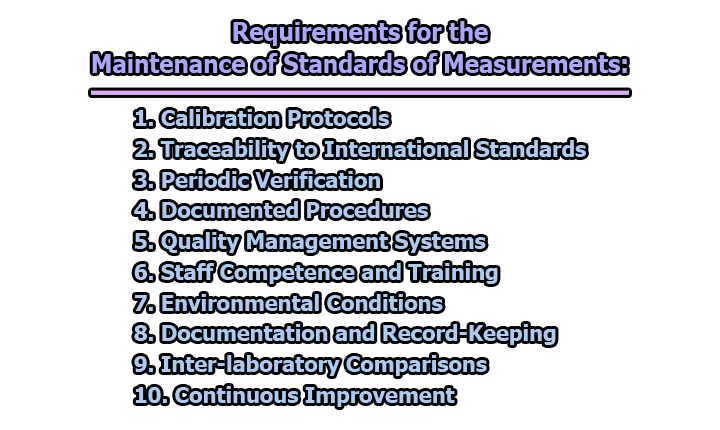

Requirements for the Maintenance of Standards of Measurements:

Accurate and consistent measurements form the bedrock of scientific, industrial, and commercial endeavors. Standards of measurements serve as the linchpin, ensuring that measurements are universally understood and can be reproduced with precision. To maintain the integrity of these standards, a meticulous system of requirements and protocols is essential. Here are some of the essential requirements for the maintenance of standards of measurements.

1. Calibration Protocols: Calibration serves as the cornerstone in the maintenance of measurement standards. This process involves comparing the measurements of an instrument to a known and accepted standard to ensure accuracy. Establishing and adhering to rigorous calibration protocols is essential for guaranteeing the reliability of measurement instruments.

Calibration begins with selecting appropriate reference standards, which are often traceable to international benchmarks. Regular intervals, typically determined by the instrument’s stability and usage frequency, are established for calibration cycles. During calibration, any deviations or inaccuracies identified are rectified to bring the instrument back in alignment with the reference standard.

The process is highly systematic, involving meticulous adjustments and measurements. Modern calibration practices often utilize advanced technology and automation to enhance precision. Calibration certificates, detailing the procedures and outcomes, are generated and retained as part of the documentation process.

2. Traceability to International Standards: The concept of traceability ensures that measurement standards are connected to internationally recognized benchmarks, fostering global uniformity. The traceability chain is crucial for establishing a clear and unbroken link from the local measurement standards to those maintained internationally.

For instance, the International System of Units (SI) serves as a universal reference point for many measurements. Calibrations must be performed using standards that can be directly or indirectly traced back to these global benchmarks. This interconnected network of traceability ensures that measurements made in one part of the world are comparable and compatible with those made elsewhere.

Laboratories engaged in calibration activities are often required to demonstrate traceability by regularly participating in proficiency testing and comparison exercises. This commitment to traceability enhances the credibility of measurements and facilitates international cooperation in science, trade, and industry.

3. Periodic Verification: Periodic verification is a crucial requirement to ensure the ongoing accuracy and reliability of measurement instruments. Over time, factors such as wear and tear, environmental conditions, and technological drift can lead to deviations in accuracy. Regular verification exercises are conducted to identify and rectify any such variations.

Verification involves comparing the instrument’s performance against predetermined criteria or reference standards. The frequency of verification depends on factors like the instrument’s criticality, stability, and usage patterns. Instruments used in critical applications may undergo more frequent verification to ensure precision.

During the verification process, adjustments are made to bring the instrument back to its specified accuracy levels. This proactive approach to maintenance not only safeguards the reliability of measurements but also contributes to the longevity of the instruments.

4. Documented Procedures: Documented procedures play a pivotal role in maintaining standards of measurements. These comprehensive documents outline step-by-step guidelines for calibration, verification, and related activities. Well-documented procedures ensure consistency, repeatability, and transparency in the maintenance process.

The calibration procedures should cover all relevant aspects, including pre-calibration checks, measurement methods, acceptance criteria, and post-calibration documentation. This documentation is crucial for training purposes, ensuring that personnel follow standardized processes and adhere to quality control measures.

In addition to calibration procedures, documentation also includes guidelines for handling and storage of measurement instruments, environmental conditions, and safety protocols. Clear and accessible documentation is essential for quality audits, enabling external parties to evaluate and verify adherence to established standards.

5. Quality Management Systems: Implementing a robust Quality Management System (QMS) is essential for organizations involved in the maintenance of standards of measurements. A QMS, often aligned with international standards such as ISO 9001, provides a structured framework for ensuring that all processes meet stringent quality control measures.

A QMS involves defining and documenting quality policies, procedures, and objectives. It includes measures for risk management, corrective and preventive actions, and continuous improvement. Regular internal audits and external certifications validate adherence to the QMS, instilling confidence in the reliability of measurement standards.

The QMS not only focuses on the technical aspects of calibration but also emphasizes the importance of customer satisfaction, staff competence, and continual improvement. By integrating a QMS, organizations can systematically enhance the quality of their calibration services, ensuring that measurement standards are consistently upheld.

6. Staff Competence and Training: Maintaining measurement standards requires a skilled and knowledgeable workforce. Calibration and verification procedures demand a high level of technical proficiency and understanding of the underlying principles. To ensure this, organizations must invest in staff competence and ongoing training programs.

Personnel responsible for calibration should undergo regular training sessions to stay updated on the latest industry standards, technological advancements, and changes in measurement protocols. This training not only enhances their technical skills but also fosters a deeper understanding of the importance of precision in measurements.

Competence assessments and certification programs can be implemented to validate the proficiency of calibration personnel. By ensuring that the staff is well-trained and competent, organizations can significantly contribute to the accuracy and reliability of measurement standards.

7. Environmental Conditions: Environmental factors play a pivotal role in the accuracy of measurements. Fluctuations in temperature, humidity, and atmospheric pressure can introduce errors in instruments, affecting their performance. Maintaining stable environmental conditions is, therefore, a critical requirement in the maintenance of measurement standards.

Calibration laboratories often invest in controlled environments equipped with climate control systems. These facilities minimize the impact of external variables on measurement instruments. Regular monitoring of environmental conditions, along with prompt corrective actions when deviations occur, is essential to uphold the precision of measurements.

The calibration process typically includes compensations for environmental conditions. However, creating a stable environment ensures that these compensations remain effective, contributing to the overall accuracy and reliability of the measurement standards.

8. Documentation and Record-Keeping: Thorough documentation and meticulous record-keeping are imperative for the maintenance of measurement standards. Every step of the calibration and verification processes, including pre-calibration checks, adjustments made, and post-calibration results, must be documented in detail.

Accurate records serve as a historical reference, allowing for the traceability of measurements over time. Calibration certificates, calibration logs, and maintenance records contribute to transparency and accountability. In the event of disputes, audits, or investigations, comprehensive documentation becomes invaluable in validating the accuracy and reliability of measurements.

Digital record-keeping systems can enhance accessibility and security of records, ensuring that they are easily retrievable when needed. Properly maintained records also support the continuous improvement process by providing insights into trends and patterns over time.

9. Inter-laboratory Comparisons: Collaborative efforts between calibration laboratories through inter-laboratory comparisons are essential for maintaining measurement standards on a broader scale. These comparisons involve multiple laboratories independently measuring the same reference standards to assess the consistency and reliability of their measurements.

Participating in inter-laboratory comparisons provides valuable feedback on the performance of measurement instruments and the accuracy of calibration procedures. Discrepancies or variations identified during these exercises can lead to improvements in calibration methodologies, contributing to the overall enhancement of measurement standards.

Inter-laboratory comparisons also foster a sense of community and shared responsibility in upholding measurement standards. By actively engaging in collaborative efforts, laboratories contribute to the establishment of best practices and the collective assurance of precision in measurements.

10. Continuous Improvement: A commitment to continuous improvement is the overarching requirement for the maintenance of measurement standards. This involves a proactive approach to regularly review and enhance calibration procedures, adopt new technologies, and integrate feedback from internal and external sources.

Regular performance reviews and audits contribute to identifying areas for improvement. Implementing corrective and preventive actions based on these reviews ensures that any shortcomings or deviations are addressed promptly. By embracing a culture of continuous improvement, organizations can adapt to evolving industry standards and technological advancements, maintaining the highest levels of accuracy in measurements.

Continuous improvement also extends to staying informed about emerging trends, research findings, and advancements in measurement science. This forward-looking approach positions organizations at the forefront of innovation, ensuring that they consistently meet or exceed the expectations for maintaining measurement standards.

In conclusion, the maintenance of standards of measurements is a multifaceted process that requires meticulous attention to detail, adherence to international benchmarks, and a commitment to continuous improvement. By implementing and upholding above requirements, the scientific and industrial communities can ensure that measurements remain accurate, reliable, and consistent, thereby fostering progress and innovation across diverse fields.

Former Student at Rajshahi University